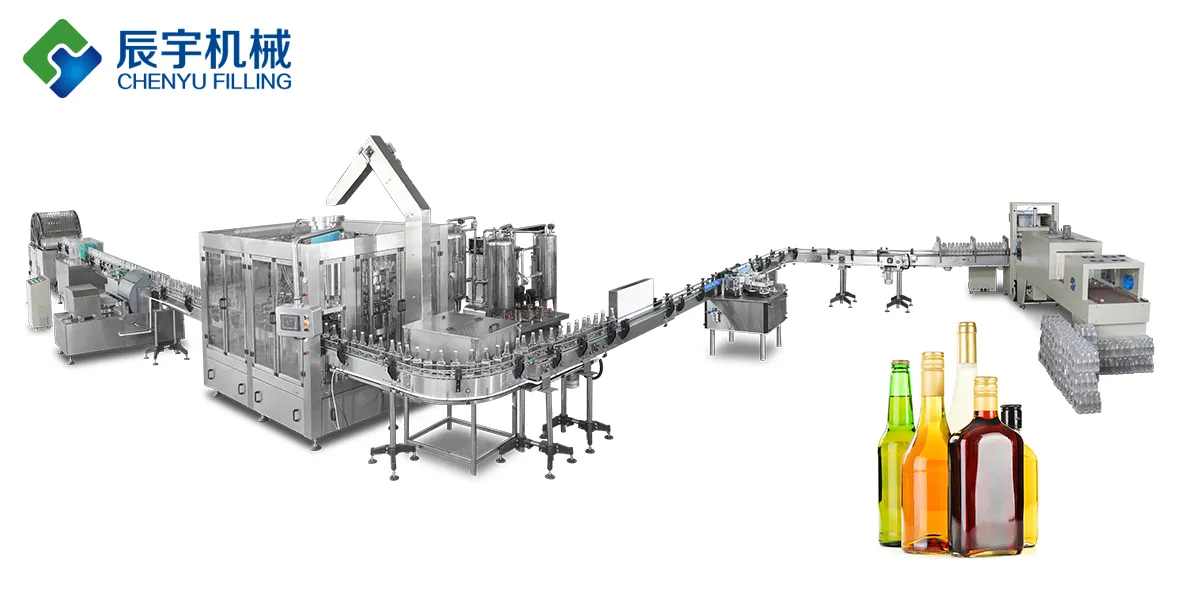

In today’s highly automated era, all walks of life are pursuing more efficient and precise production methods. For the wine production industry, the filling link is undoubtedly a crucial part. Especially the production of wine in glass bottles. How to ensure the accuracy and efficiency of every link has become the focus of major wineries. Today we will give you a detailed introduction to the glass bottle wine filling production line and how to achieve dual improvements in quality and efficiency.

1. Preliminary treatment: rigorous cleaning and disinfection

Before starting filling in the glass bottle wine filling production line, the glass bottles will first be rigorously cleaned and disinfected. Advanced robotic arms and cleaning devices are used to thoroughly clean each glass bottle. Make sure the bottle is free of any impurities and bacteria. High-temperature steam sterilization is then performed to ensure that there are no microorganisms in the bottle and provide a good environment for the subsequent filling process.

2. Filling process: high precision, zero error

The filling process of the glass bottle wine filling production line uses advanced robotic technology. The robot has a high-precision visual recognition system that can accurately find the position of the bottle mouth, ensuring the accuracy of every filling. At the same time, the robot also has an excellent trajectory planning function, which can make fine adjustments according to the size and shape of the glass bottle to ensure the smoothness of each filling.

3. Post-processing: automatic capping, labeling, and packaging

After filling is completed, the glass bottle wine filling production line will automatically perform capping, labeling and packaging. This series of actions are completed by advanced robotic arms, which greatly improves production efficiency. At the same time, due to the high precision and strong stability of the robotic arm, it can effectively avoid errors in human operation and further improve the quality of the product.

4. Intelligent management: real-time monitoring and efficient scheduling

The glass bottle wine filling production equipment is equipped with an advanced Internet of Things system. Managers can monitor the operating status of the equipment in real time through mobile phones or computers. At the same time, the system will also perform intelligent scheduling according to the production plan to ensure stable operation of the production line.

In general, the glass bottle wine filling production equipment is a double improvement in quality and efficiency. It brings new development opportunities to the alcohol production industry. By using this equipment, companies can significantly improve production efficiency and quality, reduce costs, and stand out in the fierce market competition.

Related news