Drinking water filling packing machine can fill bottles of different sizes and shapes. Drinking water filling machine is suitable for mineral water, pure water, drinking water, mountain spring water and so on. The drinking water filling machine has the characteristics of improving production efficiency, reducing manual operation, and ensuring the uniformity and reliability of the filling process.

Drinking Water Filling Machine Working Principle:

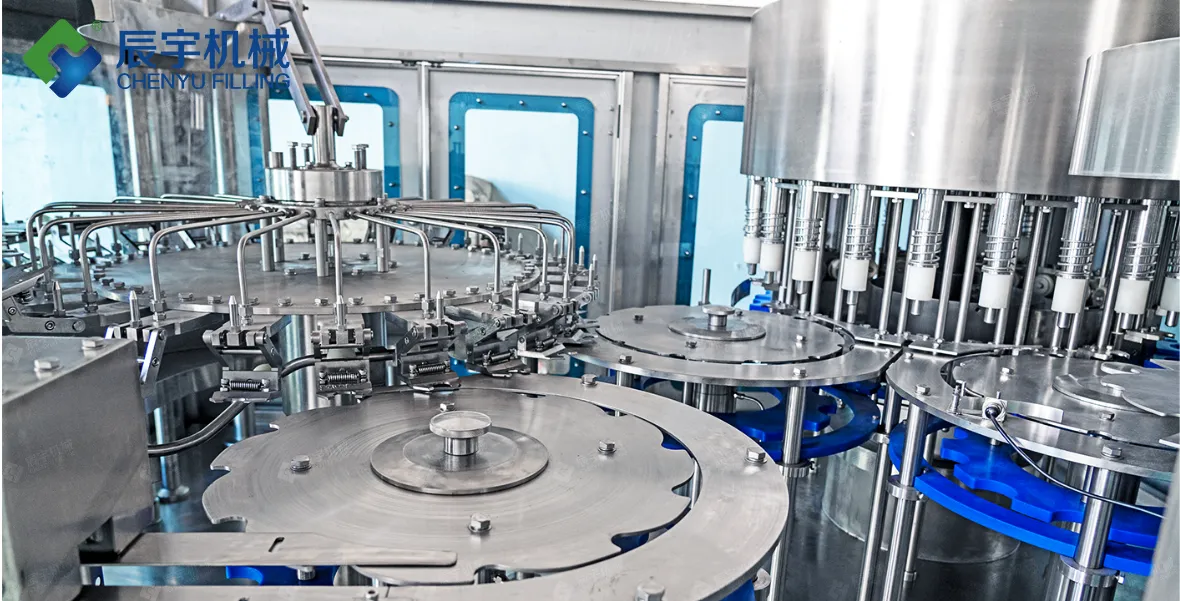

Through the mechanical arm, conveyor belt, filling valve and capping device of the drinking water filling line, water is accurately filled into the cleaned bottle; and the bottle cap is then closed to ensure hygiene and tightness.

The drinking water filling machine is also equipped with an advanced control system that enables quick switching between different filling tasks to meet the filling needs of the drinking water production line.

Drinking Water Filling Line Advantages:

1. Drinking water filling equipment adopts advanced technology, such as direct connection between the air feed path and the bottle feeding wheel; which can simplify the bottle transformation process and improve production efficiency.

2. High-precision quantitative filling valve to ensure the accuracy of the liquid level, reduce liquid loss, while ensuring the quality of filling.

3. Efficient capping system not only improves the quality of the cap, but also ensures the simplicity of operation.

4. Drinking water filling line also designed the card bottleneck into the bottle technology, effectively avoid the secondary pollution of the bottle mouth; to ensure the health and safety of the product.

5. The whole control system also has automatic functions, such as water level automatic control, missing cover detection.

Drinking water packing machine can also be used with other auxiliary equipment, such as PET blowing machine, self-adhesive labeling machine, marking machine and film machine; to form a complete drinking water filling production line.

Related news