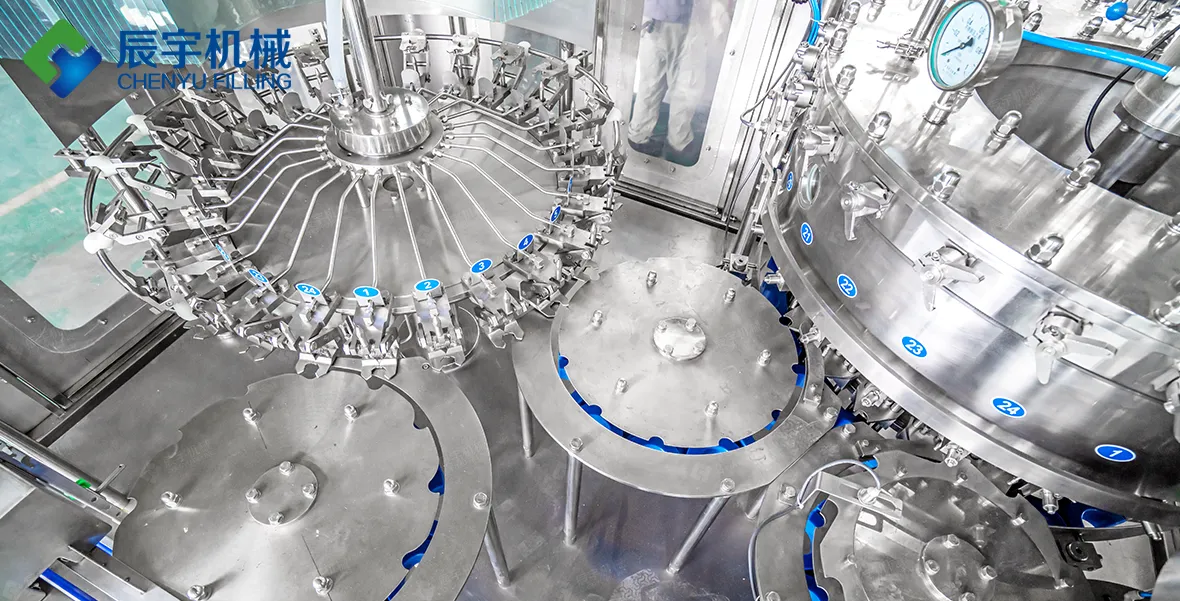

Coca cola filling machine?is used to fill carbonated beverages, such as soda, cola, sprite, fanta and other beverages. Coca cola filling line?is?usually made of stainless steel to ensure compliance with cleanliness and food safety standards.

When choosing coca cola filling equipment, factors that need to be considered include filling speed, capacity, ease of cleaning, and whether can adapt to bottles of different shapes and sizes.

Coca Cola Filling Line Working Principle:

First, the bottles are cleaned and then transported to the coca cola bottling machine, and the beverages are accurately injected into the bottles.

Next, the bottles are sealed and sometimes pressure tested with carbon dioxide to ensure the quality of the seal.

Coca Cola Filling Equipment Advantages:

1. Coca cola bottling machine can efficiently fill beverages while maintaining consistent filling volume and product quality.

2. Coca cola filling equipment is also equipped with advanced control systems that can monitor and adjust the filling process to ensure smooth and accurate operation.

3. Coca cola filling line can also be combined with other auxiliary equipment (blowing machine, labeling machine, film packaging machine) to form an automated?coca cola filling production line to improve production efficiency and reduce labor costs.

Coca Cola Filling Line Maintenance:

1. First of all, the coca cola filling line should be thoroughly cleaned regularly, especially the filling parts such as conveyor belts, filling ports and pistons, etc., to remove any possible residues. Wipe these parts with appropriate detergents to ensure their cleanliness.

2. Secondly, crucial to check whether the lubrication system is working properly. The amount and quality of lubricating oil should be checked regularly and added or replaced as needed to prevent premature wear of parts due to friction.

3. The transmission system, including chains, belts and gears, should also be regularly checked for tightness and wear, and adjusted or replaced when necessary.

4. The maintenance of the electrical system should also not be ignored. The connection and operating status of components such as electrical circuits; switches and sensors should be checked, and any damaged components should be repaired or replaced.

Related news