Can Filling Capping Machine

Product overview

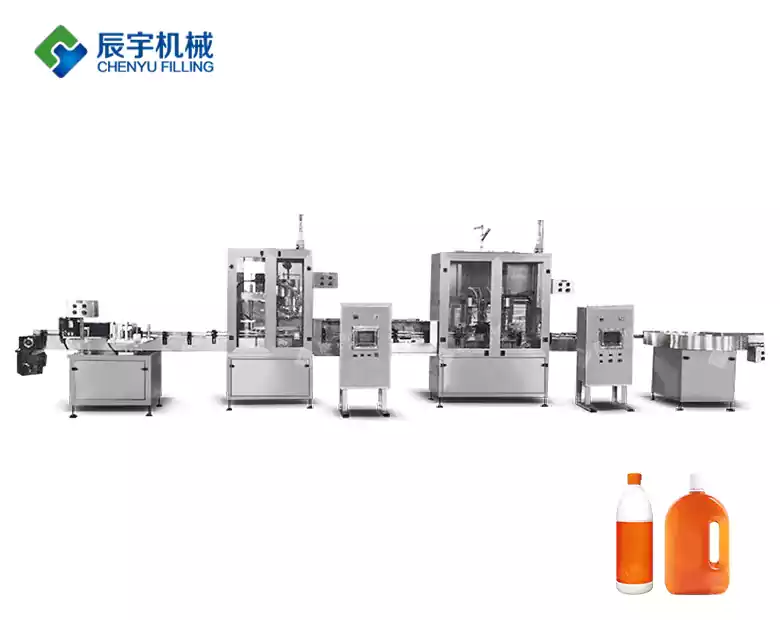

The can filling capping machine is specially designed for filling beverages such as juice in cans, and can complete the filling and sealing process quickly and accurately.

Can Filling Capping Machine video

Can Filling Capping Machine Description

The can filling capping machine is specially designed for filling beverages such as juice in cans, and can complete the filling and sealing process quickly and accurately.

The can filling machine is equipped with an advanced filling system that can ensure the freshness and taste of the juice while ensuring the hygiene and safety of the production process.

The can filling machine can also be adjusted to accommodate cans of different sizes and shapes, making it a versatile equipment in the filling industry.

During the filling process, the can filling machine adjusts the height of the filling liquid level by changing the length of the return air pipe to ensure that the amount of juice in each can is consistent. After filling, the cans will be sent to the sealing equipment for sealing to ensure the tightness of the seal and the shelf life of the product.

Can Filling Capping Machine Detail

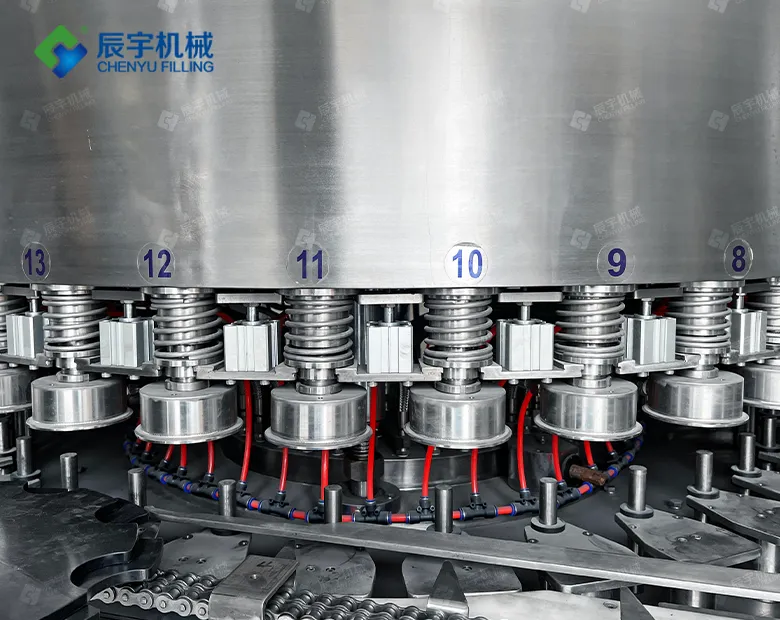

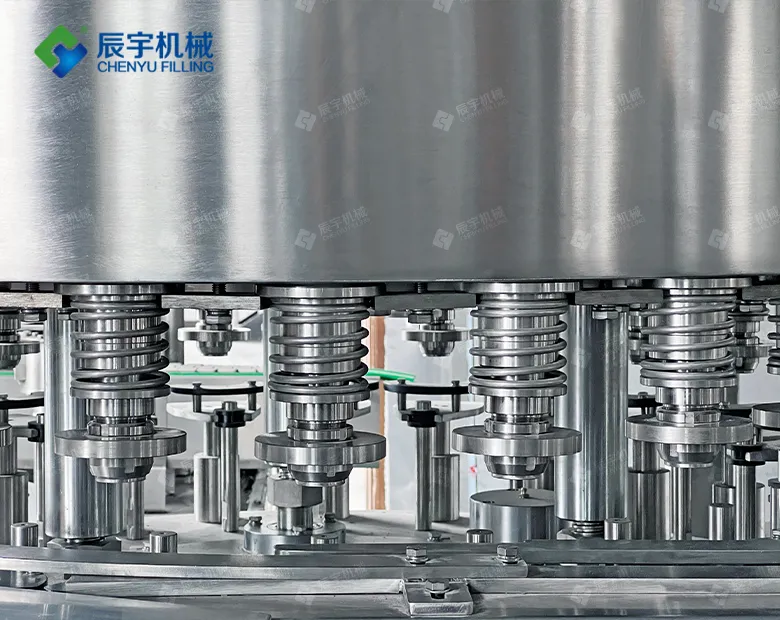

Filling Part

1. When can from in the center the star round enters a can-base of board, the filling valve taking the valve coat, the valve core is together up move, at this time 0 type roll 1 take off with the valve seat to open, enter the filling district.

2.The material continue downflow, until the bottle filling up ,when the rolls round to carry on the cam, the filling valve to move up,0 type circle 1compress tightly the valve body, make the material no longer enter the valve tube of the valve core.

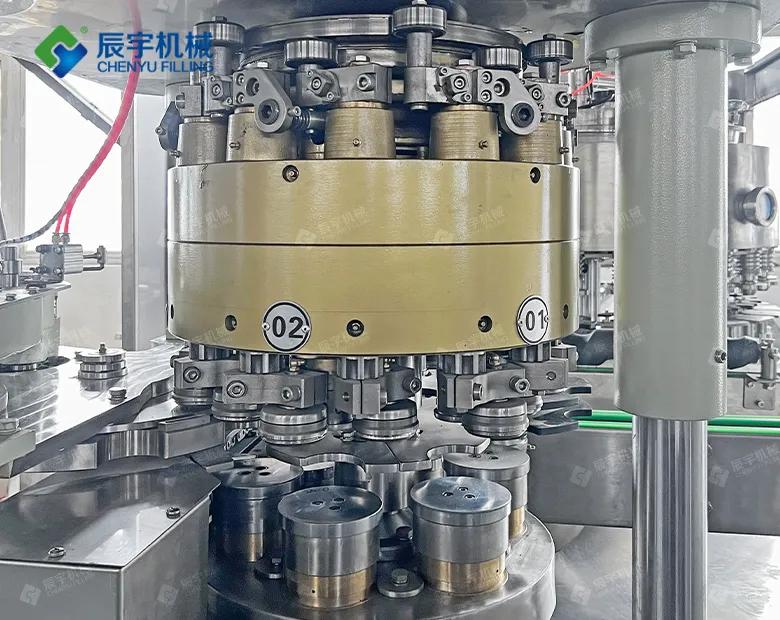

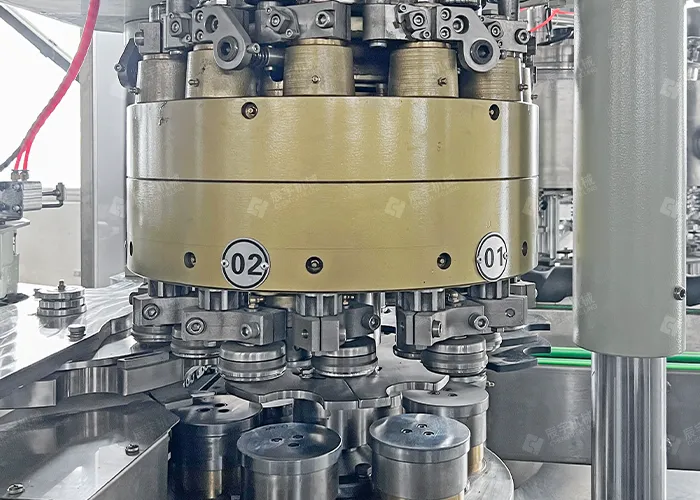

Capping Part

1. The cap screwing machine is composed of frame, slide way, cap screwing device, transmission and others.

2. The transmission of the cap screwing machine is drive to the gear by the reduce, the power is transferred to the cap screwing head through the hollow main axle.

3. The can is not rotating, the four small rolls will rotate and press cap. The cam is fixed. The cap is sent into the gear ring of the screwing cap head through the stirring device and slide way. When there is a can on the convey belt, a cap will move down with the rotating of the screwing cap head and screw the cap on the can mouth.

Can Filling Capping Machine Parameter

| Model | GDF12-4 | GDF18-4 | GDF24-6 |

| Production capacity(can/min) | 30-170 | 30-250 | 30-300 |

| Can diameter(mm) | Φ52.5-99 | ||

| Can height(mm) | 39-160 | ||

| Power(kw) | 7.5 | 7.5 | 7.5 |

| Overall dimensions (mm) | 2700x1400x1900 | 3050x1750x1900 | 3600x2200x2100 |

| Weight (kg) | 3100 | 4000 | 4000 |