I. Introduction

With the continuous development of science and technology, all walks of life are facing a new wave of automation and intelligence. In the field of wine production, fully automatic wine bottle filling machines have gradually become mainstream. With their high efficiency, precision and automation, they have greatly improved production efficiency and product quality. This article will deeply explore the design principles, advantages and application scenarios of fully automatic wine bottle filling machines.

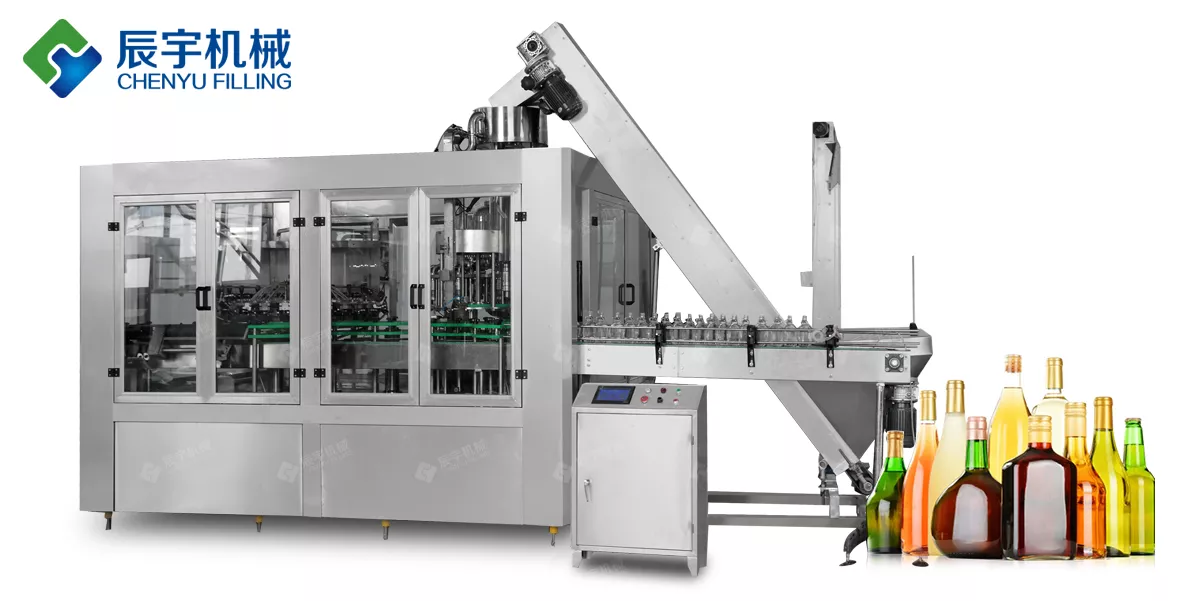

2. Design principles

The fully automatic wine bottle filling machine integrates technologies from multiple fields such as machinery, electronics, and control to realize fully automatic filling of alcoholic products. Its core parts include wine pumps, filling valves, liquid level sensors, control circuits, etc. The wine pump is responsible for providing the wine liquid, the filling valve controls the flow direction of the wine liquid, the liquid level sensor monitors the liquid level in real time, and the control circuit is the central nervous system of the entire system.

3. Advantages

Efficiency: The fully automatic wine bottle filling machine can work continuously for 24 hours, effectively improving production efficiency.

Accuracy: High-precision metering system and program control ensure that the filling amount of each bottle is accurate.

Automation: Automation of the entire process from wine delivery and measurement to filling, capping, labeling, etc. greatly reduces labor costs.

Flexibility: The fully automatic wine bottle filling machine can adapt to bottles of different specifications and types, and can achieve diversified production needs by modifying program control.

4. Application in actual production

Fully automatic wine bottle filling machines are widely used in the production lines of liquor, wine and other types of alcoholic products. In liquor production, fully automatic bottle filling machines can realize full-process automated production from raw materials to finished products, greatly shortening the production cycle. In addition, due to its high-precision metering system, it can effectively ensure the consistency and stability of product quality.

5. Conclusion

The fully automatic wine bottle filling machine is an important part of the modern wine packaging industry. With its characteristics of high efficiency, precision and automation, it has brought significant benefits to wine production companies. With the continuous development of technology, we have reason to believe that fully automatic wine bottle filling machines will play a more important role in the future wine packaging market. At the same time, for wine production companies, how to make better use of fully automatic wine bottle filling machine technology to improve product quality and production efficiency will be a topic worthy of in-depth discussion.

Related news